High-Precision Bearings Boost Intelligent Manufacturing

Core Advantages

Diverse Bearing Types for Multiple Scenarios

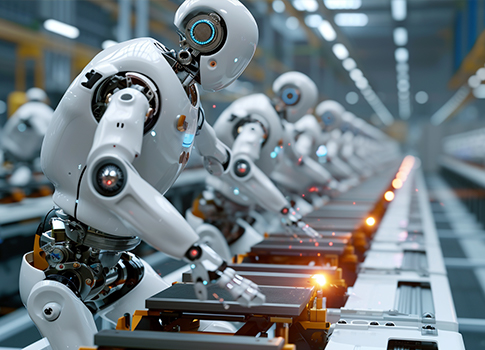

Mechanical manufacturing covers a wide range of fields. From precise machine tool processing to large-scale automated production lines, different scenarios have varying requirements for bearing performance. In the spindle system of a machine tool, high-precision angular contact ball bearings play a crucial role. They can withstand high combined radial and axial loads and possess excellent high-speed performance, ensuring that the machine tool spindle maintains minimal radial runout and axial displacement during high-speed rotation, achieving micron – or even sub-micron-level machining accuracy to meet the strict requirements of precision part processing. For the conveying devices of automated production lines, cylindrical roller bearings are the ideal choice. Their strong radial load-carrying capacity can easily handle the heavy loads brought by components such as conveyor belts and chains, ensuring smooth and stable conveying, reducing equipment vibration and wear, and improving production efficiency. In some mechanical components that need to start, stop, and reverse frequently, self-aligning ball bearings, with their self-aligning function, can effectively compensate for axis misalignment caused by installation errors or shaft deflection, ensuring stable equipment operation and extending the service life.

Excellent Performance Enables High-Quality Manufacturing

During the mechanical manufacturing process, equipment often faces challenges such as high-precision processing, long – term continuous operation, and complex working conditions. Our bearings for mechanical manufacturing perform outstandingly in terms of accuracy. By adopting advanced processing techniques and inspection technologies, we control the key dimensional accuracy within a minimal tolerance range, providing a reliable guarantee for precision manufacturing. In terms of stability, through optimized internal structure design and the selection of high-quality materials, the bearings can operate stably under high-speed and heavy-load conditions, reducing vibration and noise, ensuring that the processing process is not interfered with, and improving product quality consistency. At the same time, they have excellent durability. Through special heat treatment and surface strengthening treatment, the wear resistance and fatigue strength of the bearings are greatly improved. Even under long-term continuous operation, they can maintain stable performance, reducing the frequency of equipment maintenance and lowering production costs.

Advanced Materials and Exquisite Craftsmanship

To create high-performance bearings for mechanical manufacturing, we carefully select high-quality bearing steel as the raw material. Through advanced processes such as vacuum melting, we ensure that the material has high purity and a uniform structure, endowing the bearings with good comprehensive performance. In the manufacturing process, we use ultra-precision grinding technology, which effectively reduces the friction coefficient, improves transmission efficiency, and reduces energy consumption. The cages are made of high-strength, lightweight engineering plastics or special metal materials, and are precision injection-molded or stamped to perfectly match the rolling elements, ensuring the stability and reliability of the bearings during high-speed operation. The sealing structure uses special rubber materials and innovative designs, with excellent sealing performance, effectively blocking the intrusion of dust, oil, and other impurities, extending the bearing service life, and adapting to complex working environments.

Customized Services to Meet Individual Needs

We are well aware of the diversity and particularity of customer requirements in the mechanical manufacturing industry. Therefore, we provide comprehensive customized services. Whether you have requirements for bearing dimensions, accuracy grades, load-carrying capacity, or performance under special working conditions, our professional team will communicate with you in depth. With rich industry experience and advanced design software, we will tailor a unique bearing solution for you. From product design and R&D to sample trial production and then to large-scale production, we strictly control the quality throughout the process to ensure that each set of customized bearings can accurately meet the operating requirements of your equipment, helping your mechanical manufacturing equipment stand out in the market competition.

Choosing our bearings for the mechanical manufacturing field means choosing excellent performance and reliable quality. We look forward to working hand in hand with global partners in the mechanical manufacturing industry to jointly promote the progress and development of mechanical manufacturing technology and contribute to the prosperity of modern industry.

Empowering Intelligent Manufacturing, Driving the Future

From single-piece equipment to intelligent production lines, we provide lasting power for global mechanical manufacturing enterprises with precision bearing technology.